TRH-L-K orifice flowmeter

TRH-L-K orifice flowmeter

- 强度: 低

- 密度: 低

TRH-L-K orifice flowmeter

Widely used in process control and measurement in fields such as petroleum, chemical, metallurgy, electricity, heating, and water supply. Orifice flow meters are widely used in various fields of the national economy, such as coal, chemical, transportation, construction, textile, food, medicine, agriculture, environmental protection, and people's daily lives. They are an important tool for developing industrial and agricultural production, saving energy, improving product quality, enhancing economic efficiency, and management level. They occupy an important position in the national economy. In process automation instruments and devices, flow meters have two main functions: as detection instruments for process automation control systems and as total quantity meters for measuring material quantities.

1、 Advantages

1. The standard throttling element is fully used and recognized by the International Organization for Standardization. It can be put into use without the need for real flow calibration and is the only one in flow sensors;

2. The structure is easy to replicate, simple, sturdy, stable and reliable in performance, and inexpensive;

3. Widely applicable, including all single-phase fluids (liquid, gas, steam) and some mixed phase flows. The diameter and working state (temperature, pressure) of the general production process can be measured;

4. The detection components and differential pressure display instruments can be produced separately by different manufacturers, facilitating specialized scale production.

Image keywords

2、 Disadvantages

1. The repeatability and accuracy of measurements are at a moderate level in flow sensors, but due to the complex influence of numerous factors, it is difficult to improve accuracy;

2. Narrow range, due to the correlation between flow coefficient and Reynolds number, the general range is only 3:1 to 4:1;

3. There are long requirements for the length of straight pipe sections, which are generally difficult to meet. Especially for larger pipe diameters, the problem becomes more prominent;

4. High pressure loss;

5. The sharp angle line inside the orifice plate is used to ensure accuracy, so the sensor is sensitive to corrosion, wear, scaling, and dirt. Long term use accuracy is difficult to guarantee, and it needs to be removed and inspected once a year;

6. Using flange connections can easily lead to issues such as running, emitting, dripping, and leaking, greatly increasing maintenance workload.

热门推荐

-

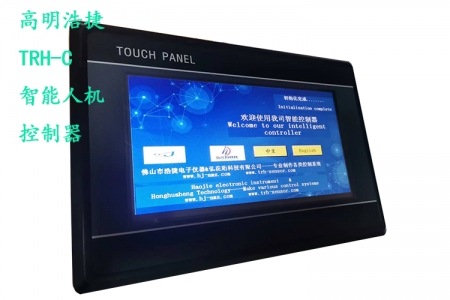

TRH-C-Steam Boiler Program Controller, Intelligent Controller, One Control Multi Intelligent Controller

-

TRH-C - Intelligent Water Level Controller, Intelligent Controller, Water Level Controller

-

TRH-C intelligent human-machine controller, program intelligent controller, touch screen intelligent controller

-

TRH-P-04 intelligent distribution cabinet, intelligent distribution cabinet host, remote power monitoring host